OUTSOURCE CREATIVE SERVICES - OUTSOURCE CREATIVE WORKS-OUTSOURCING CREATIVE WORK - OUTSOURCE CREATIVE DESIGN -OUTSOURCE 2D ARTWORKS - 2D ART SERVICES - 2D ART OUTSOURCING -ART OUTSOURCING - OUTSOURCE ILLUSTRATION WORKS - OUTSOURCE ILLUSTRATION SERVICES - OUTSOURCE 3D MODELING - 3D MODEL OUTSOURCING- OUTSOURCING CAD WORKS- OUTSOURCE ARCHITECTURAL SERVICES -BIM - REVIT - 3D FLOOR PLAN - BIM OUTSOURCING SERVICES - MEP - REVIT MODELING - 3D FURNITURE MODELING - 3D ARCHITECTURE MODELING - AUGMENTED REALITY MODEL - VIRTUAL REALITY MODEL - 3D RENDERING - PRODUCT MODELING - 2D SERVICES - OUTSOURCE CREATIVE SERVICES -3D MODELING SERVICES - VFX

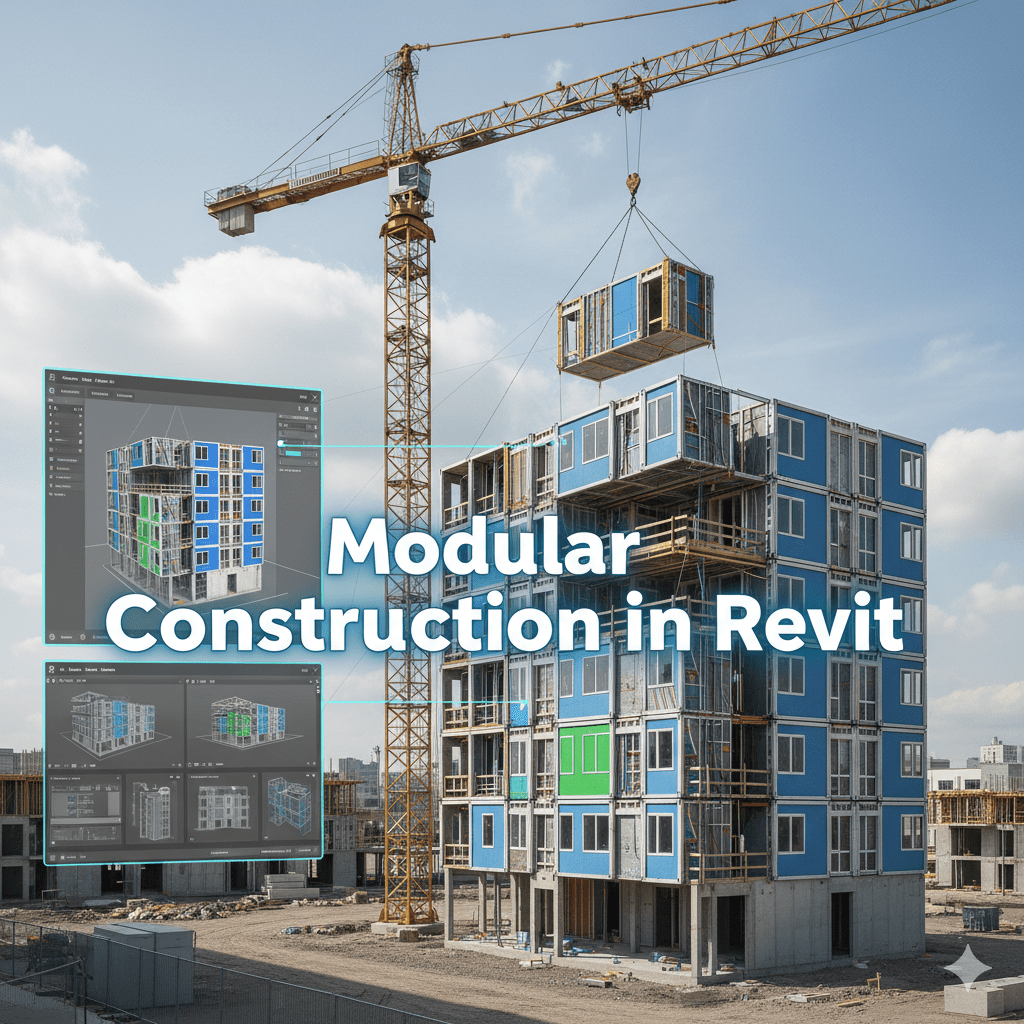

Why Modular Construction Firms Standardize Revit Workflows

The Architecture, Engineering, and Construction (AEC) industry has transformed into a complex, global ecosystem. Projects of all scales—from local infrastructure to massive, international developments—increasingly rely on a distributed workforce. Design, analysis, and detailed documentation are routinely handled by specialized external partners through Outsourcing Architectural Services. This strategic delegation offers immense benefits: access to specialized talent, cost efficiencies through leveraging global labor markets, and the ability to maintain project momentum 24/7.

However, this global distribution introduces a critical challenge: data fragmentation and interoperability. How can an architect in North America using Revit, a structural engineer in Europe using Tekla, and an external drafting team providing Outsourcing cad works in Asia using AutoCAD, all contribute accurately to the same digital building model without losing vital information?

The solution, and the bedrock of modern global AEC collaboration, is the Industry Foundation Classes (IFC) standard. IFC is the non-proprietary, open-source data model that serves as the universal language of Building Information Modeling (BIM). It is the strategic tool that ensures a seamless, accurate, and high-quality flow of information across international boundaries, making it the non-negotiable prerequisite for successful global Outsourcing cad Services.

This in-depth exploration will reveal why IFC Standardization is not just a technical box to check, but a strategic enabler that transforms workflows from simple CAD Outsourcing to sophisticated digital construction management, providing a significant competitive edge to both the client and the BIM Services provider.

The Imperative of Standardization in Modular Construction

Modular construction, which involves manufacturing buildings off-site in controlled factory conditions, is inherently about repetition, precision, and a manufacturing-driven mindset. However, without a standardized digital foundation, every project risks reverting to the bespoke, slow, and error-prone nature of traditional building. This is where the power of a standard BIM Services environment, specifically in Revit, becomes the non-negotiable cornerstone of a scalable operation.

From Project to Product: The Modular Mindset

Modular builders view a project not as a one-off custom build, but as the assembly of repeatable "products"—standardized modules or components. For this productization to work, the digital model must be equally standardized:

- Repeatability: A standard workflow ensures that the same module or connection detail is modeled and documented identically every time, irrespective of the project or the designer. This consistency is critical for the factory floor, which relies on predictable inputs for automated manufacturing.

- Scalability: When design processes are standardized in Revit, a firm can rapidly scale its output. New projects are designed not from scratch, but by assembling pre-validated, pre-costed, and pre-engineered BIM components. This drastically cuts down the time from concept to fabrication.

- Risk Mitigation: Non-standard designs introduce errors, clashes, and material waste. By standardizing in Revit, modular firms drastically reduce the chances of errors, as every part and assembly has been virtually validated before it reaches the factory. This translates directly into cost savings and fewer expensive on-site reworks.

📐 Revit: The Standardized Platform for Industrialized Design

Autodesk Revit is not merely a 3D modeling tool; it is a Building Information Modeling (BIM) platform that embeds data into every element. For modular construction, this data-rich environment is what makes standardization feasible and powerful.

1. BIM Content and Parametric Families

The most significant step in standardizing the design workflow is the creation of a Standardized Revit Family Library. These are not just geometric models; they are intelligent, parametric components representing everything from wall panels and floor cassettes to specific plumbing fixtures and electrical outlets.

- Standardized Assemblies: Modular firms create Revit Families that represent entire, pre-engineered modules. These modules contain all necessary architectural, structural, and MEP elements. Designers simply drag and drop these standardized 'building blocks' into the master model.

- Integrated Manufacturing Data: Each family is loaded with non-graphic data essential for the factory, such as material specifications, fabrication tolerances, part numbers, and links to inventory and ERP systems. This direct link from the design model to manufacturing is the true essence of a digital construction workflow.

2. Template and Output Consistency

A common challenge in large architectural projects is the inconsistency of documentation. By mandating a standardized Revit Template across all projects, modular firms ensure uniformity:

- View and Sheet Standards: All drawings—plans, sections, details, and shop drawings—look the same, regardless of who created them. This is managed through standardized view templates, plotting styles, and sheet sets within Revit.

- Naming Conventions: Rigorous standardization of file names, worksets, families, and parameters is enforced. This seemingly administrative task is crucial for team collaboration and data management, especially when leveraging Outsourcing CAD Works or Outsourcing Architectural Services. Consistent naming enables better search, filtering, and data extraction for cost and quantity takeoff (5D BIM).

3. Automated Documentation and Digital Fabrication

Once the model is standardized, the next frontier is automation. Revit’s data-rich environment enables the automation of tasks that are traditionally manual and time-consuming.

- Automated Shop Drawings: Standardized Revit workflows use tools (like Dynamo or specialized plug-ins) to automatically generate construction and shop drawings directly from the validated BIM model. This eliminates manual drafting of individual components, drastically increasing the speed and accuracy of the documentation process.

- Direct-to-Fabrication: The model data is directly exported to Computer Numerical Control (CNC) machines on the factory floor. This high level of integration—often referred to as Design for Manufacturing and Assembly (DfMA)—is impossible without a standardized, high-quality Revit model.

🤝 The Strategic Advantage: Leveraging Outsourcing CAD Works

Modular firms, driven by the need for speed and scale, are increasingly looking beyond in-house limitations. They are strategically leveraging specialized external partners through Outsourcing CAD Works and Outsourcing cad Services to maintain design momentum without compromising on the newly established standards.

Scalability and Specialization

- Demand Management: Modular firms face fluctuating project demands. Outsourcing Architectural Services for detailed modeling, documentation, or Revit family creation allows the in-house team to scale resources up or down rapidly without the burden of hiring and training full-time staff.

- Expert BIM Services: Specialist BIM Services firms often possess a deeper, broader expertise in advanced Revit applications, standardization, and coordination (e.g., complex clash detection, 4D/5D integration). By utilizing CAD Outsourcing, the modular firm gains immediate access to this high-level skill set, ensuring their standardized models are executed flawlessly and on time.

Maintaining Quality and Consistency

A common fear with outsourcing is a loss of quality or consistency. However, a standardized Revit workflow completely mitigates this risk.

"When a modular firm's BIM standards are clearly documented and embedded within a master Revit Template, the outsourced team becomes an extension of the in-house system. They are not creating a design; they are systematically applying a pre-defined standard to a new project."

The outsourced partner receives the firm's specific Revit template, standardized family library, and BIM Execution Plan (BEP). Their deliverable is a model that conforms precisely to the firm’s standards, ensuring seamless integration back into the client’s digital construction workflows. This strategic partnership, facilitated by Revit Services, is key to achieving a high-quality, continuous production pipeline.

📊 The Financial and Operational Impact

The move to standardize Revit workflows is not merely a technical preference—it is a significant business decision with measurable financial and operational returns.

1. Cost Predictability (5D BIM)

Modular construction's core benefit is its cost predictability. A standardized Revit model enables 5D BIM, integrating cost data directly into the design workflow.

- Automated Quantity Takeoffs (QTO): Since every element is a standardized, data-rich Revit Family, accurate and instant quantity takeoffs are possible directly from the model. This eliminates manual estimation errors.

- Factory Efficiency: Standardized components mean consistent material procurement and manufacturing processes, reducing material waste and enabling bulk purchasing, which ultimately drives down the cost per module.

2. Enhanced Coordination (Clash Detection)

In a factory setting, even minor clashes are costly, as they disrupt an automated assembly line.

- Preemptive Clash Resolution: Standardization and a shared Revit model allow for rigorous and efficient clash detection between architectural, structural, and MEP services (4D and 5D BIM). Because the components are standard, a conflict resolved once is resolved for all future projects using that same standard assembly.

3. Faster Time-to-Market (4D BIM)

Speed is a top market differentiator for modular construction.

- 4D BIM Integration: Standardized design data can be easily linked to project scheduling software (4D BIM), allowing for the simulation and optimization of the factory production and on-site assembly sequence. This visibility ensures that the right module arrives at the site at the exact right time (Just-in-Time delivery), maximizing construction speed.

Conclusion: The Future is Standardized and Digital

Modular construction is fundamentally an industrial process operating within the construction industry. To succeed and scale, it must adopt the principles of high-volume manufacturing: standardization, automation, and a data-driven approach.

The standardization of design workflows in Revit is the essential first step on this path. It transforms an unpredictable design process into a reliable digital input for the factory floor, minimizing errors, slashing costs, and dramatically accelerating project timelines.

By intelligently integrating specialized partners through Outsourcing cad Services—leveraging their BIM Services and Revit Services expertise to flawlessly execute these standardized designs—modular firms are not just building faster; they are building smarter. They are creating a scalable, digital blueprint that is redefining the very future of the built environment.

For businesses looking to transition to this modern, efficient model, embracing standardized Revit workflows and exploring the strategic advantages of CAD Outsourcing is the clearest path to unlocking profitability and market leadership.

❓ FAQs on Modular Construction and Revit Standardization

1. What is the main reason modular firms use Revit standardization?

Modular firms standardize their design workflows in Revit primarily to ensure repeatability, accuracy, and efficiency, treating building modules as standardized products for automated factory production. This dramatically reduces on-site errors and accelerates project timelines.

2. How does standardizing the design workflow reduce costs?

Standardization enables high-accuracy Quantity Takeoffs (QTO) directly from the Revit model (5D BIM), minimizes material waste through precise component design, and reduces expensive reworks by eliminating design clashes early in the process.

3. What role do Revit Families play in this standardization?

Revit Families are used to create a standardized library of pre-engineered, data-rich components and entire modules. Designers assemble projects using these pre-validated blocks, ensuring consistency and linking the design directly to manufacturing and procurement data.

4. What are the benefits of using Outsourcing Architectural Services for a standardized workflow?

Outsourcing Architectural Services allows modular firms to scale their design capacity quickly without hiring internal staff. By using the firm's standardized Revit templates and BIM standards, the external team ensures consistency while providing access to specialized BIM Services expertise.

5. What does the term "Digital Construction Workflows" mean in this context?

It refers to an end-to-end digital process where the standardized Revit model serves as the single source of truth, connecting design decisions to factory-based fabrication, automated machinery (CNC), construction scheduling (4D BIM), and cost management (5D BIM).

6. Is CAD Outsourcing still relevant if a company uses BIM/Revit?

Yes, CAD Outsourcing is highly relevant. It provides essential support for tasks like converting legacy 2D drawings into Revit, developing complex standardized Revit Services family content, and handling overflow drafting or detailing work, all while adhering to the firm's strict BIM standards.

No comments:

Post a Comment